I’m doing more work with SIPs panels in California and am wondering if there could be future capability within PlusSpec of creating walls & floors that have a polystyrene core, OSB sheathing both sides, and no studs. Currently using Profile Builder 3 to create the panel and going back and replacing all of the PlusSpec walls and floors with the PB3 created panel, doubling my work.

Thanks

Hi Drew, yes, using Profile Builder and drawing over PlusSpec geometry is a slow way to do it.

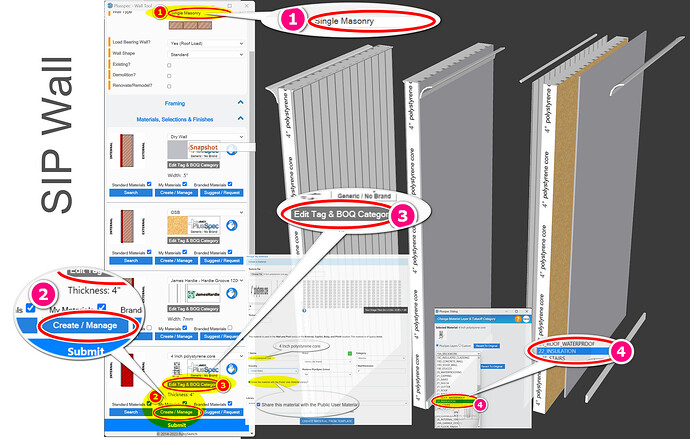

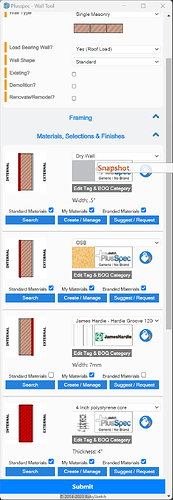

You can do it in PlusSpec a lot quicker by changing the core of either Single masonry or the Solid wall.

You could then start drawing from scratch, and the material will be quantified; there are 3 ways to draw SIPS in PlusArchitect and PlusDesignBuild.

-

Use the Grid tool to mark the panel spacing and click on each grid when drawing. My tip would be to use the Grid tool before starting the design to ensure you make the most efficient use of standard panels. (Sips can be very efficient and economical if the designer designs with standard panel sizing in mind) w

-

Creating a cladding material with a defining line in the texture at the SIP join will be quicker. It depends on the output you are looking for.

-

Some Sip panels have an insulated core with a 4x4 stud on each join, and the cladding and baseboard are nailed to the 4x4. In this case, I would use a lightweight framed wall and change my stud spacing to the panel size minus half 2inches

Awesome! Thanks so much, Andrew. I’ll give it a go.

No problem.

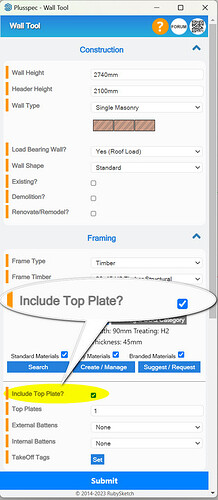

I assume the panels you are drawing with have an integrated top plate/ribbon plate? If this is the case, Click on “Framing” choose a section size and tick “Include Top Plate.”

If the top plate and or bottom plates are continuous across multiple walls, use the beam tool and use “flip plate”. Then override the cladding step downs to the thickness of the timber (wood framing) member

Yes, they will have a bottom and top plate. I use the flip plate for my mud sill on top of the foundation. Great point about using that for the bottom and top plates of the panels too. I’ll definitely do that.

I see that the inside wall will provide the “wallpaper” of the OSB, so I created a 1" thick drywall to accommodate the 1/2" OSB thickness so the interior dimension is correctly represented. I just have to make a note on the takeoff that 1" represents standard 1/2" thickness.