Hi Beta Testers,

This is where you can comment and give your thoughts about our Beta Truss Tool.

Kind Regards

Dean

Hi Beta Testers,

This is where you can comment and give your thoughts about our Beta Truss Tool.

Kind Regards

Dean

Very impressive!

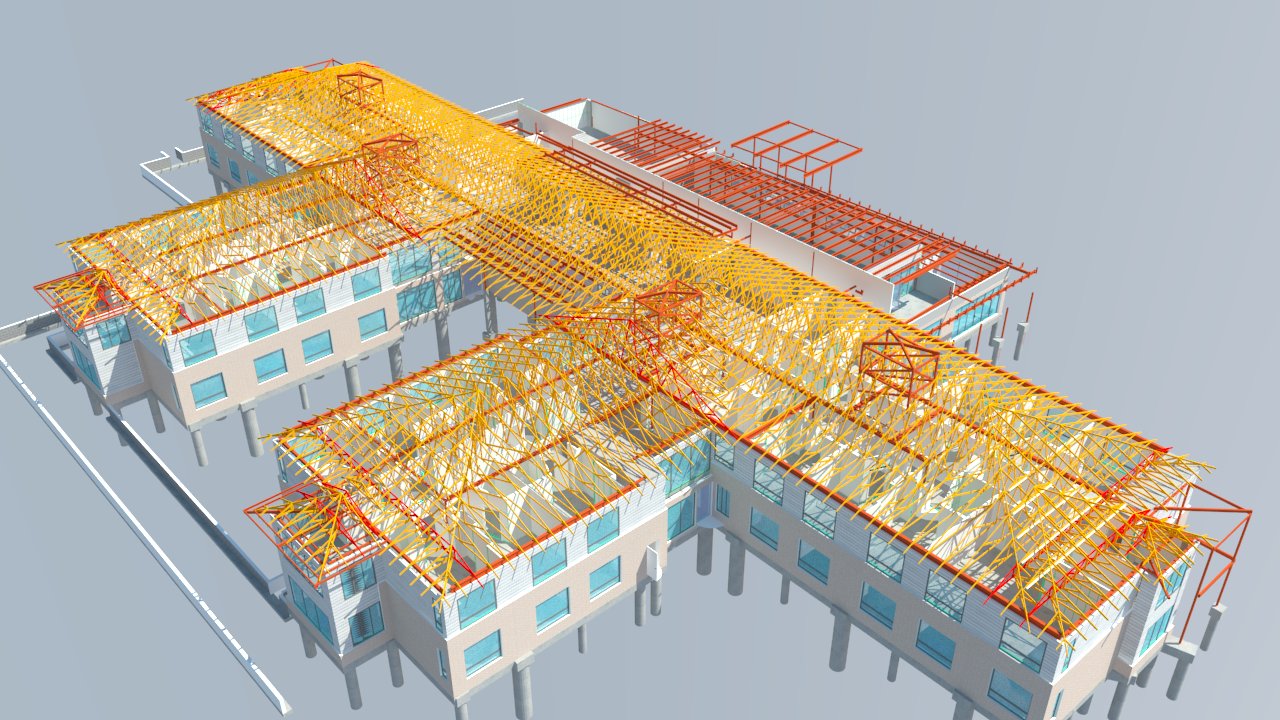

Over 2000m2 of trusses in about 35mins and that was essentially processing downtime.

Haven’t been able to break it yet

Thanks

Hi Daniel,

Great to hear and your model looks really good and seems like there is a lot of great information inside of it.

Thanks for the feedback and keep up the great work ![]()

Kind Regards

Dean

Hi guys,

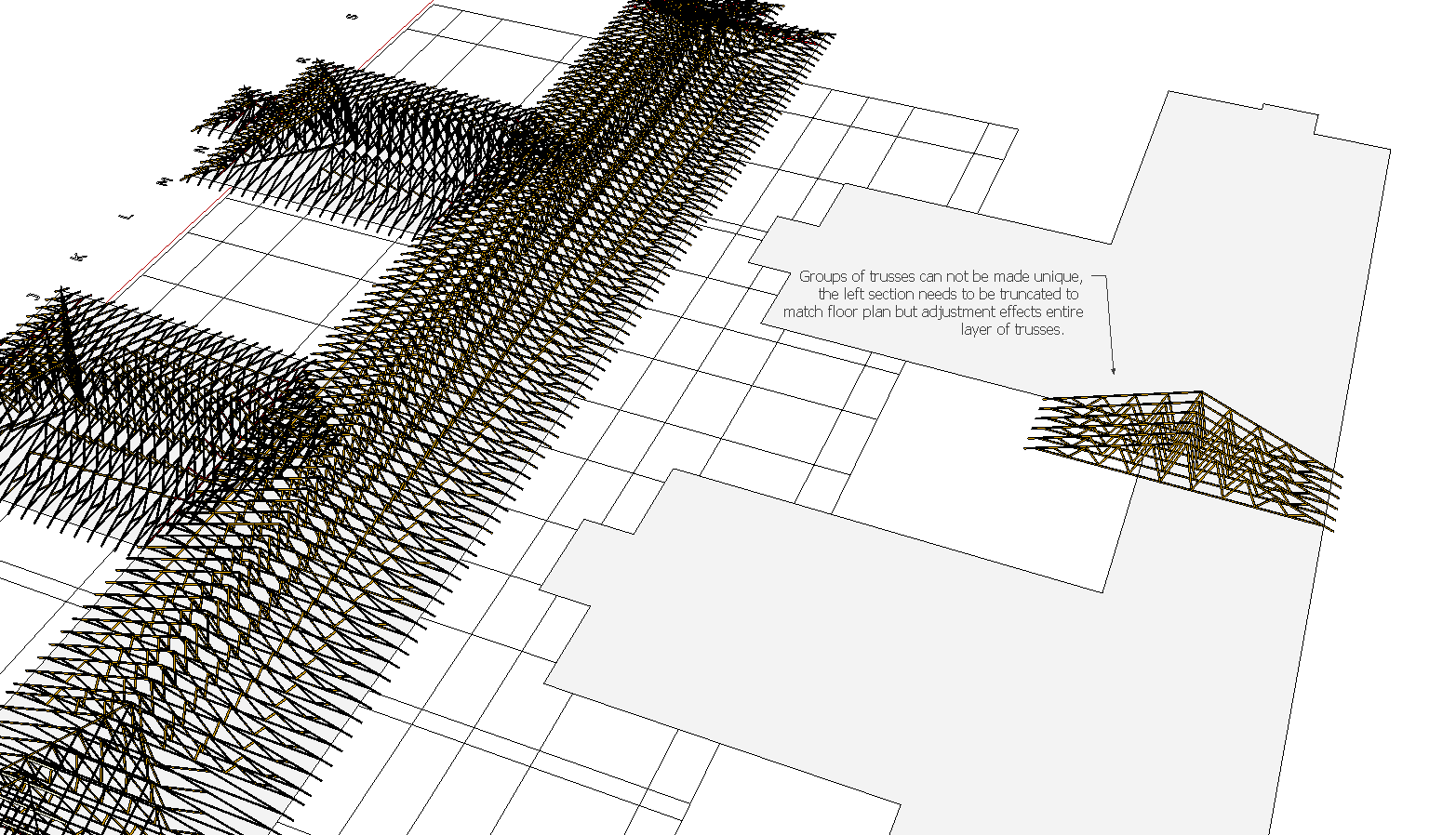

I can edit the individual groups of trusses but cannot make them unique, is there a work around here?

Thanks

Hi Daniel,

I came across a similar issue… it is solvable. The trusses appear to be made of multiple components… ie components within components. It is a matter of drilling down through these (I use the double click method) to isolate them and then you can do the normal “right click” and make unique.

Hope this helps,

Zorro

Thanks Zorro,

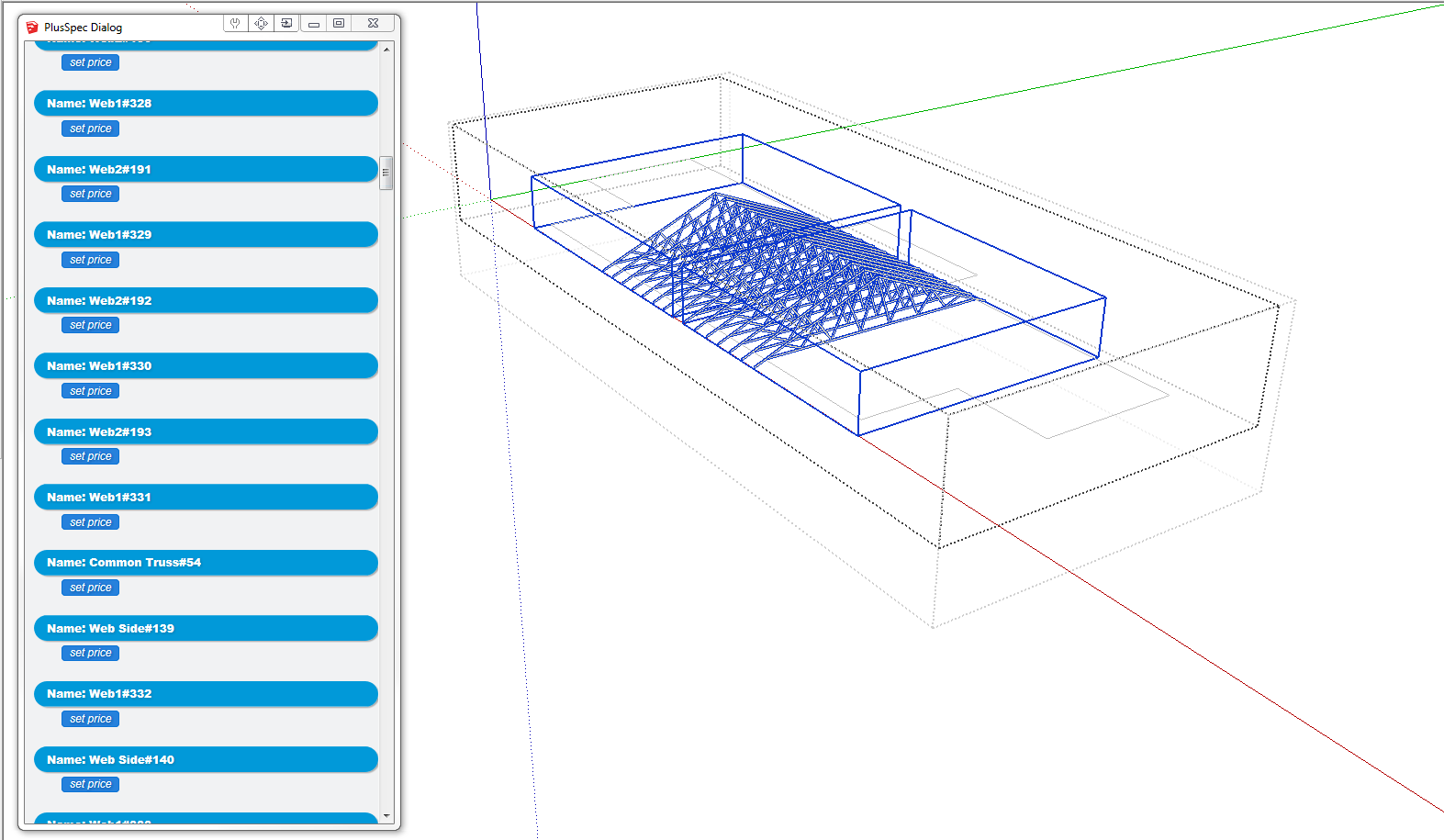

Further to that, the entire truss (if not the specific group) needs to be a complete component with the ability to be unique. The BOQ is measuring every individual component within the truss at the moment, thats not easy to rate.

Cheers

Hi Daniel and Zorro,

What is the reason for needing to make a truss unique? Is it something that we can create so it saves the users from needing to do this also?

Kind Regards

Dean

Hi Dean,

First off I think building the trusses in groups is a fantastic way of simplifying a really daunting task!

It’s just when the auto calculate group isn’t quite right that these groups would really benefit from being unique. I.e. the trusses in image 2 need to truncated and penetrations for light shafts in image 1 need to be trimmed out and It’d be fairly easy manual fix if those individual trusses were unique.

Ideally;

Thanks

Hi Dean,

I was also wished to truncate several trusses where a separate adjoining entrance roof met the main roof.

The other work around I used (apart from drilling in to components as above post) was to create separate truncated trusses and slot them in to replace the original ones that needed altered. Would be easier and quicker if you could just isolate the truss needing changed, make it unique, then right click on it and select an “edit truss” option to bring up the truss tool and make needed amendments,

Zorro

Hi Guys,

Thank you for taking the time to write your reply and help PlusSpec.

I am going to send Andrew an email so that he can chime in.

How did you want the SketchUp to Excel quantities output to read once creating the unique truss?

Kind Regards

Dean

Hi Dean,

I guess logically I’d want the amended truss to be highlighted as it’s own entity in the TakeOff reports. Ideally it would be extremely functional if when you create the amended truss you were able to give it a name/number reference that was carried through to reports.

Zorro

Hi guys thanks for commenting. If we drew the trusses from a face we would be able to automate the penetrations and that was my first preference, yet it was filled with complexities and results that i did not anticipate. I knew we would come up with these type of questions and have remedied a few of them. We will make an individual truss tool that allows you to add in special trusses that will be present in your estimate or BOQ. I also believe the trusses should have a tool like redefine or push pull so they can be shortened where penetrations occur.

I think a good start would be the individual truss tool as it will allow you to use the 3 point truss configurer and stop the draw at the penetration opening, then use the individual truss tool to fill in the blanks. This way your BOQ or Excel export of Trusses or components from PlusSpec / Sketchup will be accurate.

Just so you know we are continuing to work on this and we will get you guys a beta version before official release.

I am sure you are aware that an engineer needs to actually design the trusses? Please do not build from them without and engineers certification. We could also add in nail plates and girder boots automatically. We do have dutch gables working yet it is still in alpha as we have are testing in house. I will keep you posted.

Thanks for posting, it really does help. ![]()